Premium Natural Healthy 100% Beef

Jagua Sticks Bully Sticks are crafted from fresh, single-ingredient beef pizzle, offering a purely natural dog treat.

Premium Natural Healthy 100% Beef

Jagua Sticks Bully Sticks are crafted from fresh, single-ingredient beef pizzle, offering a purely natural dog treat.

OUR PRODUCTS

ALL-NATURAL PREMIUM BEEF PIZZLE

Hand-sorted and packed in the USA, distributed by Jagua Sticks Corp. Miami, Florida 🇺🇸

We manufacture our own bully sticks so we can maintain the best quality control with the best ingredients.

Free from preservatives, chemicals, hormones, and grains, they’re ideal for dogs of all life stages and breeds.

Created for easy digestion, these bully sticks make great dog chew sticks, reducing the risk of stomach upset or digestive issues commonly associated with other treats.

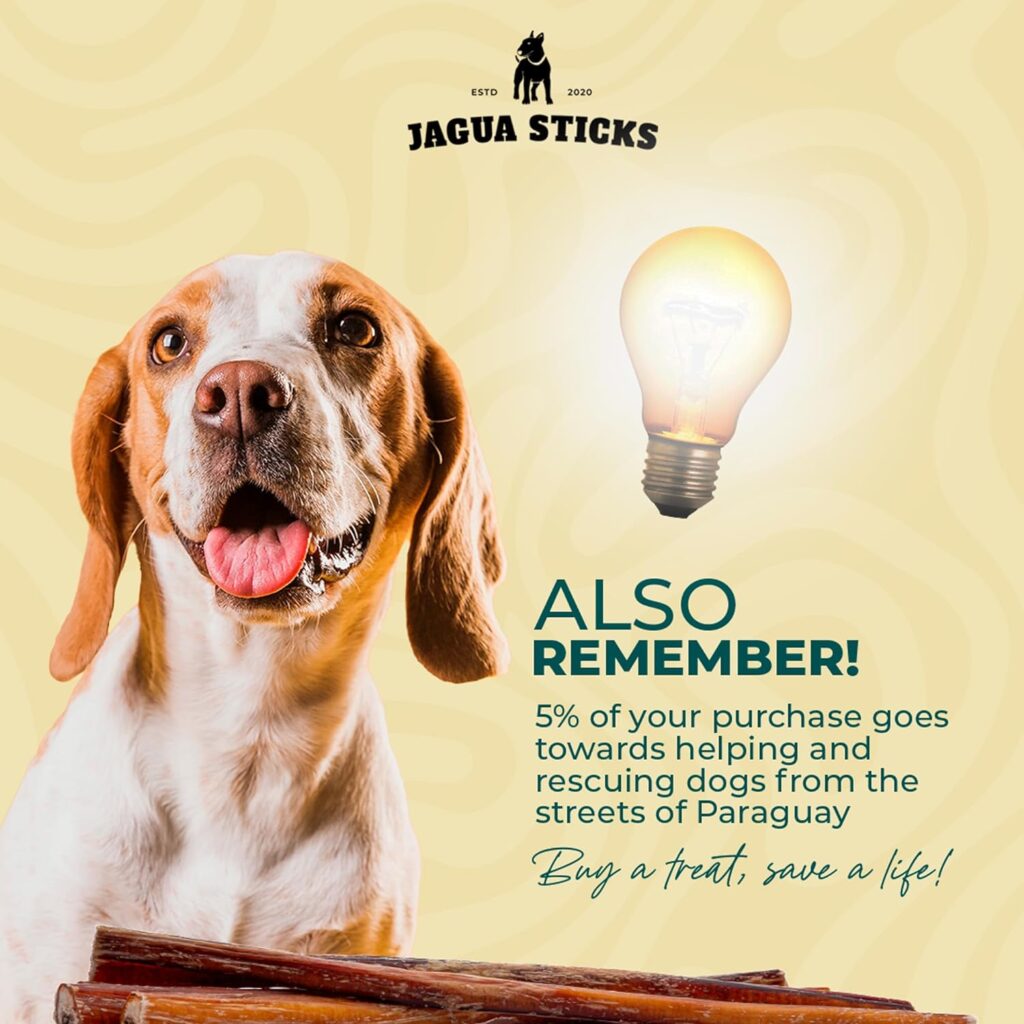

With every purchase of our all-natural bully sticks, a percentage goes towards rescuing dogs from the streets in Paraguay. Enjoy giving your dog a delicious treat while contributing to a noble cause.

Jagua sticks are some of the best dental chews for dogs. Regular chewing of these dental chew bully sticks helps in maintaining dental hygiene by reducing plaque and tartar buildup, leading to stronger teeth and healthier gums for your dog.

Made by Jagua Sticks Corp. in Paraguay, the manufacturing plant is owned and operated by Jagua Sticks Corp.

Manufacturing Process

The manufacturing process for bully sticks typically involves several steps to transform raw beef pizzle into the finished chew treats that dogs enjoy. Here’s an overview of the general manufacturing process:

- Sourcing: The process begins with sourcing high-quality beef pizzle, which is the main ingredient used to make bully sticks. The pizzle is obtained as a byproduct of the beef industry.

- Cleaning and Inspection: Once the beef pizzle is obtained, it undergoes a thorough cleaning process to remove any dirt, debris, or contaminants. The pizzle is inspected to ensure it meets quality standards and is free from any visible defects.

- Cutting and Shaping: The cleaned beef pizzle is then cut and shaped into the desired sizes and shapes for the bully sticks. This may involve cutting the pizzle into uniform lengths and either leaving them straight or braiding and twisting them for added texture.

- Drying or Cooking: The cut and shaped beef pizzle is then subjected to a drying or cooking process to remove moisture and kill any harmful bacteria. Drying is achieved through air-drying and oven-drying methods.

- Quality Control: Throughout the manufacturing process, quality control measures are implemented to ensure the safety and consistency of the bully sticks. This include monitoring temperature and humidity levels during drying or cooking, conducting microbial testing to check for contaminants, and inspecting the finished product for any defects.

- Packaging: Once the bully sticks are dried or cooked to the desired specifications and have passed quality control checks, they are packaged for distribution. Packaging involves sealing the bully sticks in individual or bulk packaging to maintain freshness and prevent contamination.

- Labeling: Finally, the packaged bully sticks are labeled with clear and informative labeling that helps pet owners make informed decisions about the products they purchase for their pets.

Overall, the manufacturing process for bully sticks involves careful attention to detail and adherence to quality standards to produce safe, high-quality chew treats for dogs.

TESTIMONIALS